triple organic evaporator OVD-3

discontinued product!!!

Layers of organic molecules have increasingly become the focus of the application-oriented surface science and chemistry. Not lastly, the growing efficiency of electronic components such as solar cells and displays, whose compounds are organic molecules, has greatly increased the demand for cost-effective evaporator cells for laboratory applications and small series production. However, conventional evaporator cells are mainly designed for a temperature range which is much too high, so that they can hardly be operated at temperatures at which organic molecules sublimate in a vacuum.

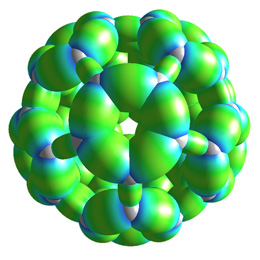

With the organic evaporator OVD-3, ventiotec offers a product which is optimized for this segment. Thanks to the compact design, three independently controlled evaporation units can be quickly heated up and again cooled down. In the process, the consistent shielding of the evaporator units minimizes the thermal crosstalk. The gas emission of the source is minimal even at 600°C and does not disturb the ultra high vacuum. The special design of the rotary aperture thereby allows for the simultaneous evaporation of one, two or three units. This guarantees the full flexibility with the smallest possible dimensions. The three-fold evaporator should be mounted to a standard DN35CF flange. The usage of CF flanges thus provides for the unrestricted application in the ultra-high vacuum.

Precisely in laboratory applications, a quick change of the samples which are being prepared also poses an enormous time advantage. Therefore, a special version of the OVD-3 exists, which can be pumped down separately from the usual vacuum system using a by-pass. In this way, the evaporator can be dismounted from the usual vacuum system and filled separately. This assures a clean preparation of the layers. A high stability of the particle flux is guaranteed by the usage of a PID controler.

Specifications:

• 3x quartz crucibles each with 30 mm³ filling volume

• Ta-filament direct electrical heating (resistive)

• filaments can be controlled separately

• recommended temperature range from 100°C to 600°C

• integrated shutter for the opening of one or two crucibles

• one type K thermocouple per crucible

• mounted on flange DN35CF

• working distance between flange and shutter: approx. 210 mm (long version) or 110 mm (short version)

• pump ports, linear adjustment and valves are available separately upon request

• working distance between shutter and specimen: 50 to 100 mm

• compatible with ultra-high vacuum

• suited for: Fullerene (C60 or C70), Perylene derivatives (PTCDA, Dimethyl-PTCDI), Phthalocyanine (CuPc)

discontinued product!!!

control unit OVD-1 control

discontinued product!!!

The OVD-1 control is a temperature controller, which is especially designed for our OVD-3 evaporator, but can also be universally used. With the compact device a crucible can be exactly operated in each case. Three control devices can be integrated side-by-side in a standard 19” rack. The connections for the thermocouple and the filament supplies are positioned on the front side and are thus easily accessible. In this way, the three crucibles of an OVD-3 vaporizer can be easily controlled sequentially with one OVD-1 control.

A PID controller which is controlled by a micro-controller from WiKa, a company with long lasting tradition, assures the precise control of the vaporizer cells. This is naturally equipped with an integrated self-optimization algorithm. This is equipped with a two-line, easily legible LED display. On these two lines, the setpoint and actual values are simultaneously displayed in contrasting colors. The essential parameters are thus quickly ascertainable at all times. The setpoint can be easily set using the push button under the display.

Moreover an amplifier stage, which extensively linearizes the control path, is connected downstream of the regulator, which works with a analog output signal. This guarantees that the controller optimally functions precisely in the overall range between 100°C and 600°C. In this way, an overshooting of the temperature during heating up of the crucible can be minimized and the heat-up time is kept short.

Specifications:

• PID controller with analog output signal and self optimization from WiKa, a company with long lasting tradition

• extensive linearization of the control path

• type K thermocouple input

• output is current-limited

• maximum output voltage: Umax=12V

• maximum heating output (with OVD3) approx. P=30W

• design as 19“ rack plug-in units

• filament breakage detector